Forklift Safety Signs-- Clear Communication for Safe Forklift Procedures

Forklift Safety Signs-- Clear Communication for Safe Forklift Procedures

Blog Article

Secret Factors To Consider for Designing Effective Forklift Safety Indications

When creating reliable forklift security indicators, it is vital to consider several basic variables that collectively guarantee optimal exposure and quality. Strategic positioning at eye level and the use of durable materials like aluminum or polycarbonate further contribute to the long life and performance of these indications.

Shade and Contrast

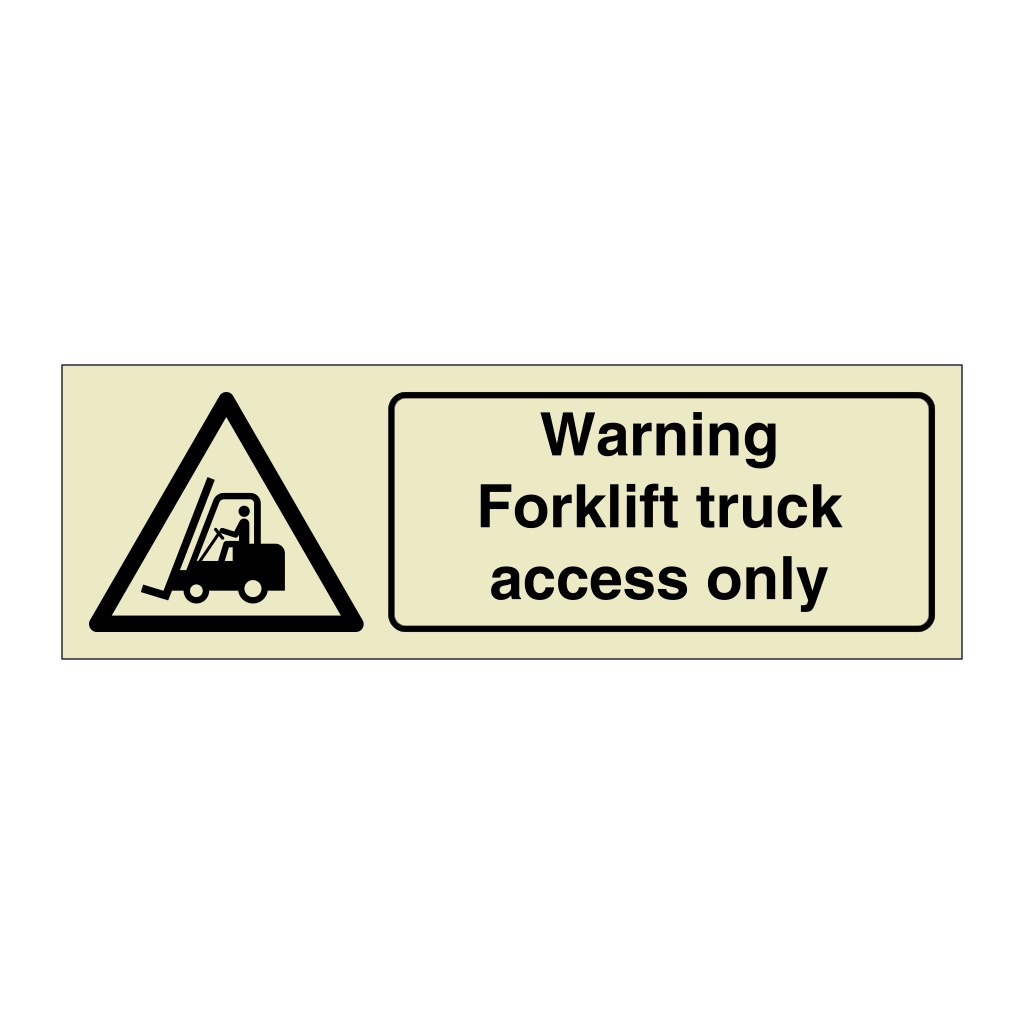

While making forklift security signs, the choice of shade and comparison is paramount to making certain presence and effectiveness. The Occupational Safety And Security and Wellness Administration (OSHA) and the American National Specification Institute (ANSI) provide standards for using shades in safety indications to standardize their meanings.

Reliable comparison between the history and the message or signs on the sign is similarly important (forklift signs). High comparison ensures that the indication is understandable from a range and in varying lights problems.

Using suitable color and comparison not only follows regulative standards but additionally plays an essential function in maintaining a secure workplace by making certain clear communication of hazards and instructions.

Font Style Size and Design

When developing forklift safety indicators, the choice of typeface dimension and design is vital for making sure that the messages are readable and quickly recognized. The main purpose is to improve readability, specifically in settings where quick data processing is crucial. The typeface dimension need to be huge enough to be checked out from a distance, fitting differing sight problems and making certain that workers can comprehend the indicator without unneeded strain.

A sans-serif font is normally recommended for safety and security indications due to its clean and simple look, which enhances readability. Fonts such as Arial, Helvetica, or Verdana are often liked as they lack the intricate information that can cover essential information. Consistency in font design throughout all safety and security indicators aids in creating an attire and specialist look, which additionally enhances the importance of the messages being conveyed.

Furthermore, focus can be accomplished with strategic use of bolding and capitalization. By meticulously choosing proper font style sizes and styles, forklift security signs can properly communicate essential safety details to all employees.

Placement and Exposure

Making sure optimum placement and visibility of forklift safety and security signs is paramount in commercial setups. Correct sign positioning can dramatically decrease the threat of mishaps and enhance general work environment security. First of all, indications need to be placed at eye degree to ensure they are conveniently obvious by drivers and pedestrians. This typically means positioning them in between 4 and 6 feet click to find out more from the official statement ground, depending on the ordinary height of the workforce.

Signs must be well-lit or made from reflective products in dimly lit locations to guarantee they are visible at all times. By meticulously thinking about these elements, one can make sure that forklift security indicators are both efficient and visible, consequently fostering a much safer working environment.

Product and Toughness

Choosing the right materials for forklift safety indicators is crucial to ensuring their longevity and performance in commercial settings. Given the extreme problems often run into in warehouses and making facilities, the products chosen must hold up against a variety of stressors, including temperature level variations, moisture, chemical direct exposure, and physical influences. Sturdy substratums such as light weight aluminum, high-density polyethylene (HDPE), and polycarbonate are preferred choices due to their resistance to these elements.

Aluminum is renowned for its effectiveness and rust resistance, making it a superb selection for both interior and outdoor applications. HDPE, on the other hand, supplies outstanding effect resistance and can withstand extended exposure to severe chemicals without degrading. Polycarbonate, understood for its high influence strength and quality, is often made use of where presence and resilience are vital.

Equally vital is the kind of printing made use of on the indicators. UV-resistant inks and protective coatings can dramatically improve the life expectancy of the signs by stopping fading and wear triggered by prolonged exposure to sunshine and various other ecological variables. Laminated or screen-printed surface areas offer extra layers of defense, ensuring that the crucial security information stays understandable in time.

Buying top notch materials and durable production processes not just extends the life of forklift safety and security indicators yet also enhances a culture of safety within the office.

Compliance With Regulations

Complying with governing criteria is critical in the layout and deployment of forklift security indications. Conformity makes sure that the indications are not only effective in communicating essential security info yet likewise fulfill legal obligations, consequently reducing possible obligations. Different companies, such website here as the Occupational Security and Wellness Management (OSHA) in the United States, give clear standards on the requirements of safety signs, consisting of color systems, message dimension, and the inclusion of globally identified signs.

To follow these laws, it is necessary to conduct a comprehensive review of appropriate criteria. OSHA mandates that safety and security indications have to be visible from a range and consist of certain colors: red for risk, yellow for caution, and eco-friendly for safety directions. Additionally, adhering to the American National Criteria Institute (ANSI) Z535 series can additionally enhance the performance of the indications by standardizing the design components.

Furthermore, normal audits and updates of security signs need to be executed to make sure ongoing conformity with any adjustments in regulations. Involving with certified safety professionals throughout the design phase can additionally be valuable in making certain that all regulative demands are met, and that the indicators offer their intended purpose efficiently.

Verdict

Creating effective forklift safety indicators needs mindful attention to shade contrast, font size, and design to make certain optimum exposure and readability. Adherence to OSHA and ANSI guidelines systematizes safety messages, and incorporating reflective materials raises visibility in low-light situations.

Report this page